Worm Gearbox for Wave Energy Conversion Systems: Superior Performance and Durability

A worm gearbox is a critical component in wave energy conversion systems. Notable for their compact design, high torque, and impressive durability, these devices are integral for efficient and reliable energy generation. In this article, we delve into the characteristics and functions of worm gearboxes, with a particular emphasis on their application in wave energy conversion systems.

Key Features of Worm Gearbox

- Durability: Worm gearboxes are designed for long-term use, withstanding harsh environments associated with wave energy conversion.

- High Torque: These devices deliver high torque output, essential for efficient power generation.

- Compact Design: Their compact design makes them ideal for applications where space is limited.

- Quiet Operation: Worm gearboxes operate quietly, minimizing noise pollution.

- High Reduction Ratios: They offer high reduction ratios, improving the efficiency of energy conversion systems.

Why Worm Gearbox for Wave Energy Conversion Systems?

- Efficiency: The high reduction ratios offered by worm gearboxes enhance the efficiency of wave energy systems.

- Robustness: Their strong and durable construction ensures reliable operation in harsh marine environments.

- Space-Saving: Their compact design allows for easy installation in confined spaces.

- Low Maintenance: Worm gearboxes require little maintenance, reducing operational costs.

- Smooth Operation: They ensure smooth and quiet operation, reducing wear and tear on the system.

Working Principle of Worm Gear Motor

The worm gear motor operates by converting high speed, low torque input into low speed, high torque output. This is achieved through the interaction of the worm (a screw-like gear) and the worm wheel (a larger gear with teeth that mesh with the worm).

Selecting the Right Worm Gear Reducer

- Load Requirements: Choose based on the load requirements of your system.

- Environmental Conditions: Consider the operating environment, as this can affect the longevity and efficiency of the gearbox.

- Space Availability: The available space for installation will dictate the size and type of gearbox you can use.

- Cost: Factor in the initial cost, as well as maintenance and replacement expenses.

- Manufacturer Reputation: Choose a reputable manufacturer to ensure quality and reliability.

Motors for Worm Gear Reducers

The right motor for a worm gear reducer is crucial for optimal performance. These two components work hand in hand, and their compatibility determines the efficiency and lifespan of your system. We also provide high-quality electric motors to complement our worm gear reducers.

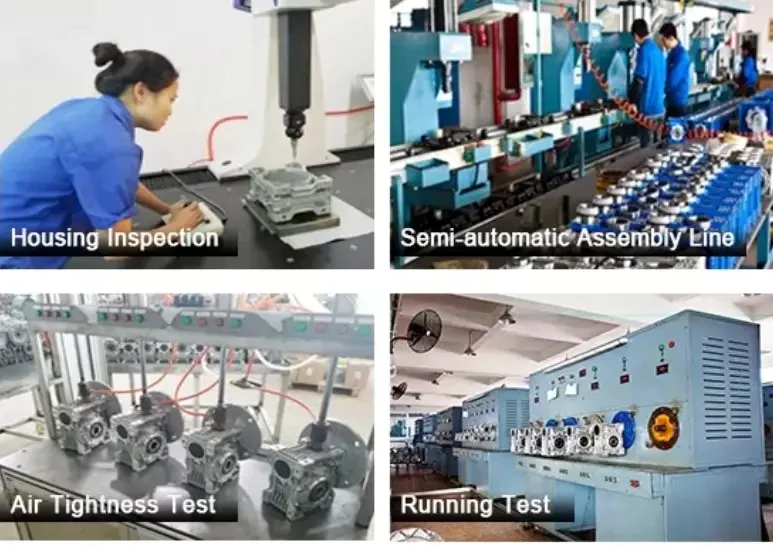

Choose Us for Quality Worm Gearboxes

We are a leading manufacturer of transmission equipment with over 15 years of experience. Our products are trusted by customers across Europe, America, Africa, and Asia for their superior quality, competitive prices, and excellent service. We offer a range of worm gear reducers, including the MRV series, GV series, and more. Explore our products and contact us to make a purchase.

FAQs

- Q1: What is the lifespan of a worm gearbox?

- A: With proper maintenance, our worm gearboxes can last for many years, even in tough environments.

- Q2: How do I know which worm gearbox is right for my system?

- A: Factors such as load requirements, space availability, and environmental conditions will determine the right gearbox. Our experts can assist you in selecting the best fit for your needs.

- Q3: Do you provide installation services?

- A: Yes, we do provide professional installation services to ensure optimal performance.

Edited by Zqq.