Worm Gearbox for Geological Core Sample Drills

The worm gearbox is an essential component in geological core sample drills. Known for its durability, efficiency, and high torque output, it plays a crucial role in the operation of these drills. This gearbox is specifically designed to withstand tough drilling conditions, offering an exceptional performance that sets it apart from standard gearboxes.

Main Features of the Worm Gearbox

- It provides high torque output which is essential for drilling into hard geological formations.

- The gearbox is designed for high efficiency, ensuring optimal power is used during drilling operations.

- With a robust and compact design, the gearbox can withstand tough drilling conditions.

- It offers smooth and quiet operation, reducing noise pollution at the drilling site.

- The gearbox is easy to maintain, ensuring a long lifespan and reducing downtime.

Applications and Benefits of the Worm Gearbox

Worm gearboxes are ideal for geological core sample drills due to the following reasons:

- They provide the necessary torque and rotational speed needed for drilling operations.

- The gearboxes offer high efficiency, reducing energy consumption and operation costs.

- With their robust design, worm gearboxes can withstand the tough conditions of drilling operations.

- They provide smooth and quiet operation, ensuring a comfortable working environment.

- Worm gearboxes are easy to maintain and have a long lifespan, reducing the need for frequent replacements.

Working Principle of the Worm Gear Motor

The worm gear motor works on the principle of a worm (a screw-like device) engaging with a gear/wheel. The worm rotates, and this rotation is transferred to the gear. The gear's rotational motion is slower but has greater torque. This is how a high torque output is achieved, which is essential for core drilling operations.

Choosing the Right Worm Gear Reducer

- Consider the torque requirements of your drilling operation. A higher torque requirement means a larger gearbox may be needed.

- Consider the operating conditions. The gearbox should be able to withstand the environmental conditions of the drilling site.

- Take into account the gearbox efficiency. Higher efficiency gearboxes may have a higher initial cost but can save energy and operating costs in the long run.

- Consider the noise level. For a comfortable working environment, choose a gearbox that operates quietly.

- Consider the maintenance requirements. Gearboxes that are easy to maintain can save time and costs associated with maintenance.

Motors for Worm Gear Reducers

Worm gear reducers and motors work hand in hand to achieve the desired drilling operation. The motor drives the worm, which in turn drives the gear in the gearbox, providing the required torque and speed. Understanding this symbiotic relationship is crucial for optimal performance. We also offer a range of high-quality electric motors specifically designed to work with our worm gear reducers.

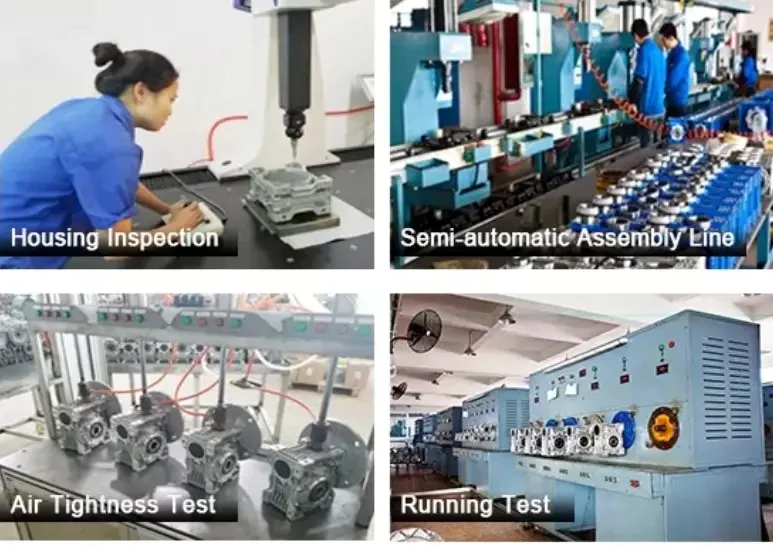

About Our Company

We are a comprehensive transmission equipment manufacturer with over 15 years of experience. We serve customers in Europe, America, Africa, Asia, and have gained a reputation for our exceptional quality, competitive pricing, and excellent customer service. We specialize in the production of various types of reducers, including our MRV series worm gear reducer, which is widely used in industries such as equipment, food, car washing, packaging, transmission, automation, and solar energy. Explore our range of products today and experience the difference for yourself.

Frequently Asked Questions

Q1: What is the lifespan of your worm gearboxes?

A1: Our worm gearboxes are designed for a long lifespan, but the exact lifespan can depend on the operating conditions and maintenance.

Q2: Can your worm gearboxes withstand harsh drilling conditions?

A2: Yes, our gearboxes are robustly designed to withstand tough drilling conditions.

Q3: Do you provide custom solutions for specific drilling needs?

A3: Yes, we can provide custom gearboxes tailored to your specific drilling needs.

Please don't hesitate to contact us for more information and to place an order. We are committed to providing the best solutions for your drilling operations.

Edited by Zqq.