Worm Gearbox for Dynamic Architectural Lighting

The worm gearbox is an essential component in dynamic architectural lighting systems. It provides efficient power transmission and precise control, enabling the creation of stunning lighting displays. This writeup will delve into the key features, applications, working principle, and selection guide for worm gearboxes.

Key Features of Worm Gearbox

- Durable: Made from high-quality materials, ensuring long-term reliability in various operating conditions.

- Efficient: Offers high torque output and low energy consumption, making it ideal for energy-intensive applications.

- Compact: Its design allows for easy installation in tight spaces without compromising performance.

- Quiet Operation: Operates with minimal noise, contributing to a quieter working environment.

- High Precision: Provides precise control over the speed and direction of rotation, crucial in dynamic architectural lighting.

Applications of Worm Gearbox in Dynamic Architectural Lighting

- Flexibility: Can be integrated into various lighting systems, enabling the creation of diverse lighting effects.

- Control: Provides precise rotational control, critical in achieving accurate light positioning and movement.

- Efficiency: Offers efficient power transmission, ensuring optimal lighting performance with minimal energy waste.

- Safety: Its sturdy construction reduces the risk of mechanical failures, enhancing the safety of lighting installations.

- Cost-Effectiveness: Its durability and efficiency reduce maintenance and energy costs over the long term.

Working Principle of Worm Gear Motor

The worm gear motor works on the principle of speed reduction. The worm (a gear in the form of a screw) meshes with the worm wheel, causing it to rotate. The rotation speed of the worm wheel is significantly reduced compared to the worm, providing a high torque output.

How to Select the Suitable Worm Gear Reducer

- Application Requirement: Consider the specific needs of your application, such as the required speed, torque, and operating conditions.

- Size: Ensure the reducer fits into the available space in your system.

- Materials: Choose a reducer made from materials that can withstand your operating conditions.

- Efficiency: Look for a reducer that offers high efficiency to minimize energy usage.

- Cost: Balance between initial purchase cost and long-term operating costs.

Motors for Worm Gear Reducers

Worm gear reducers and electric motors complement each other. The electric motor provides the initial rotational movement, which the worm gear reducer then reduces to achieve the desired speed and torque. We also offer compatible electric motors for our worm gear reducers.

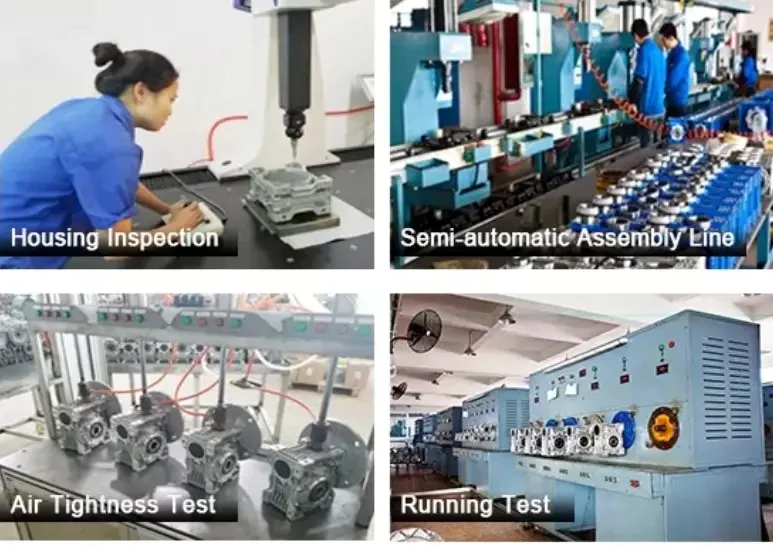

We are a leading manufacturer of transmission equipment, including the worm gearbox for dynamic architectural lighting. Serving customers across Europe, America, Africa, and Asia for over 15 years, we are committed to providing the highest quality products at competitive prices. Our continuous innovation and strict quality control have earned us a strong reputation in the market.

Experience the difference of our worm gearboxes today! Contact us now to explore and purchase our products.

Q&A

- Q1: Can the worm gearbox be customized to fit my application?

- A1: Yes, we can customize the worm gearbox to meet the specific requirements of your application.

- Q2: How energy efficient is the worm gearbox?

- A2: Our worm gearboxes are designed for high efficiency, ensuring optimal performance with minimal energy consumption.

- Q3: What after-sales support do you provide?

- A3: We provide comprehensive after-sales support, including product warranty and technical assistance.

Edited by Zqq.